Teflon ® coating

Like many great human inventions, Teflon® was discovered by chance: while Dr Roy J. Plunkett was experimenting with a coolant in 1938, he observed that a compressed, frozen TFE (tetrafluoroethylene) sample polymerised in a beaker, giving rise to the first known fluoropolymer: polytetrafluoroethylene (PTFE). This new material presented high chemical and thermal resistance, apart from having other extremely useful properties. It was patented by DuPont in 1941 with the name Teflon® and was mainly marketed in the form of bakeware items.

Teflon ® product range, properties and benefits

All the PTFE Teflon® coatings are made without PFOA and can be used in continuous temperatures reaching maximum values up to 260°C. There is a wide offer available, particularly in the kitchenware sector:

The original Teflon® Classic has non stick properties and excellent value for money in everyday use. It is a bilayer system of at least 25 microns.

Teflon® Select lasts longer as it is designed for more intensive use: it is a trilayer system with a minimum thickness of 35 microns.

Teflon® Xtra is a reinforced coating system.

Teflon® Platinum is even more resistant to abrasion and scratching, as it withstands the use of metal utensils and even abrasive scouring pads. It is also a trilayer system with a thickness of up to 40 microns and microparticles of an extremely hard material.

In recent years Teflon® has continued to offer innovations such as Teflon® Infinity, a four-layer system with a modern, attractive stone finish in different colours, and Teflon® Profile which, although a trilayer system, has greater resistance to scratching thanks to a unique technology and a wrinkled appearance similar to the skin of a reptile.

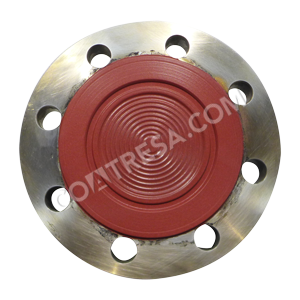

Teflon® industrial non-stick coatings can be applied using spray techniques, in both liquid and powder form, and are so versatile that they can be applied to parts with a wide variety of sizes and shapes. It can also be combined with other materials that have different properties, adding specific benefits for special needs. So if we consider its benefits such as its high thermal resistance, chemical inertness, good dielectric stability and low friction coefficient, Teflon® non-stick coatings are perfect for the industrial sector as when applied, their friction coefficients may reach 0.02- 0.15, depending on the load, speed and coating type. Furthermore, the use of Teflon fluoroplastics is beneficial in manufacturing semi-conductive materials: in addition to Teflon® PTFE, products such as Teflon® PFA and Teflon® FEP can be used, which protect from corrosion in multiple aggressive industrial processes, such as those used in the chemical industry.

Some of our works at Teflon®

Teflon® Industrial Coating References

420G-104 Gray

420G-106 Metallic Gray

420G-106 Silver

420G-109 Metallic Black

420G-703 Black

532-1003 Black

532-6114 Green

532G-13032 Gray

532G-13054 Ruby Red

532G-5010 Clear

532G-5011 Clear

532G-5310 Clear

532G-7000 Clear

532G-8000 Clear

532G-8110 Clear

532G-8410 Clear

699N-129 Black

850G-204 Gray

850G-305 Black

850G-314 Green

850G-321 Gray

851G-214 Green

851G-221 Gray

851G-224 Green

851G-255 Black

852G-201 Clear

852G-202 Clear

855G-021 Blue

855G-023 Black

855G-101 Black

855G-103 Black

855G-402 Black

855G-500 Clear

855G-501 Pewter

855G-510

855G-512

856G-200 Clear

856G-203 Black

856G-204 Green

856G-410 Clear

857G

857G-030 Black

857G-040 Black

857G-100 Black

857G-110 Clear

857G-130 Pewter

857G-135 Black

857G-140 Black

857G-210 Clear

857G-230 Sparkling Black

857G-240 Clear

857G-310 Green

953G-401

953G-401 Pewter

953G-506 Dark Violet

954G-101 Light green

954G-103 Black

954G-201 Green

954G-203 Black

954G-300 Clear

954G-302 Gray

954G-303 Black

954G-304 Green

958G-203 Black

958G-303 Black

958G-306 Blue

958G-313 Black

958G-406 Black

958G-414 Green

959G-203 Black

959G-204 Green

959G-205 Brown

978G-403

978G-406